- Straight to your door!

Straight to your door

A diamond drill bit is your go-to tool when you need to cut through seriously hard materials like stone, concrete, or that porcelain tile you've been putting off. Unlike a standard bit that tries to bulldoze its way through, a diamond bit uses tiny industrial diamond particles bonded to its tip to grind through tough surfaces with incredible precision. This unique approach lets it create clean, smooth holes where other bits would just give up.

To really get why diamond bits are in a league of their own, you have to rethink what "drilling" actually is. A standard twist bit is all about brute force—it acts like a miniature chisel, chipping and tearing material away. That works fine for wood or soft metals, but try it on granite, and you'll end up with cracks, chips, and a useless, burnt-out bit.

A diamond drill bit, on the other hand, works more like a high-speed grinder. It doesn’t chip away at the material; it abrades it. The cutting edge is fused with thousands of tiny, super-hard industrial diamonds. As the bit spins, these diamonds methodically wear down the target surface, turning it into a fine powder or a slurry if you're using water.

Think of it like using sandpaper versus a chisel on a block of wood. The chisel rips out big chunks fast but you risk splintering everything. The sandpaper slowly and smoothly sands the surface down, giving you total control and a flawless finish. A diamond drill bit is the sandpaper of the drilling world—precise, powerful, and clean.

This grinding action is the secret sauce. It’s what lets you drill perfect holes in brittle materials without shattering them to pieces.

The real magic of a diamond drill bit lies in how those diamond particles are stuck to the metal body (the shank). This process, called bonding, is everything when it comes to performance and how long the bit will last. The metal matrix holding the diamonds is cleverly designed to wear away at just the right speed, constantly exposing fresh, sharp diamond crystals at the cutting edge.

This controlled erosion is what keeps the bit cutting effectively trip after trip. It’s this smart bit of material science that gives a diamond bit its two defining traits:

Once you grasp that a diamond bit works by grinding, not chipping, you're on your way to getting the most out of it and choosing the right one for those tough jobs.

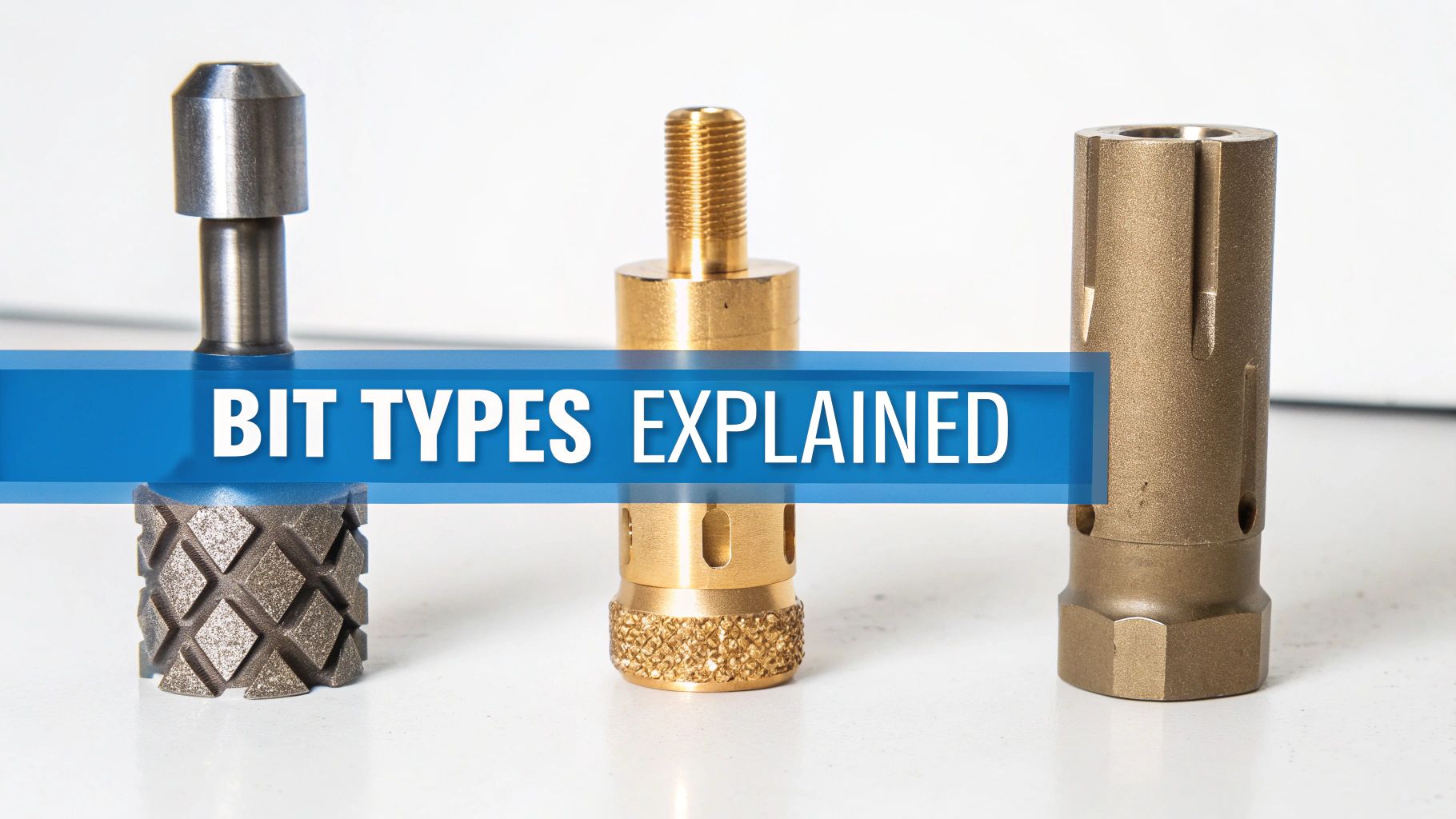

Not all diamond drill bits are created equal. Far from it. The way the diamonds are bonded to the bit’s body completely changes how it performs, how long it lasts, and what jobs it’s cut out for.

Getting your head around the main types—electroplated, vacuum brazed, and sintered—is the key to matching the right tool to your specific job. It’s about getting a clean cut without wasting time, money, or your materials. Some bits are specialists, designed for delicate, precise work where a fine finish is everything. Others are absolute workhorses, built to chew through the toughest construction materials day in and day out.

Electroplated bits are all about a delicate touch. They’re made by securing a single layer of diamonds to the bit's surface using a nickel coating process. This gives them an incredibly sharp cutting edge, perfect for drilling through highly fragile materials like glass, ceramic, and those delicate porcelain tiles that can shatter if you just look at them wrong.

The trade-off? Because only that single outer layer has diamonds, their lifespan is shorter. Think of them as a specialist tool, the scalpel in your toolkit for jobs where precision and avoiding chips are far more important than long-term durability. They require minimal pressure and are almost always used with water to keep things cool and prevent damage.

Vacuum brazed bits are a serious step up in toughness. In this process, diamonds are bonded to the bit’s exterior in a vacuum furnace, forging a much stronger connection than you get with electroplating. This means they can cut more aggressively, much faster, and for a whole lot longer.

These bits are remarkably versatile, happy to tackle everything from hard porcelain and marble to cast iron. A lot of them are even designed for dry cutting, which is a massive bonus for on-site work where dragging a water supply around is a pain. For anyone needing a reliable, do-it-all diamond drill bit, a quality vacuum brazed diamond holesaw is an excellent place to start.

When the job gets serious, you bring in the sintered bits. These are the undisputed heavyweights of the diamond drilling world. During manufacturing, diamond particles are mixed right into a metal powder and then fused together under intense heat and pressure. The result is a solid, multi-layered diamond segment that is incredibly tough.

The real magic of a sintered bit is that as the top layer wears down, new diamond particles from the layer underneath are exposed. It effectively re-sharpens itself as you work. This gives them the longest lifespan by far.

They are the go-to choice for professionals drilling through reinforced concrete, granite, and other hard stone in high-volume construction or quarrying work. Sintered bits are a proper investment, but one that pays off in long-term performance on the toughest jobs imaginable.

To make sense of it all, here’s a quick comparison to help you pinpoint the right bit for your needs.

| Bit Type | Manufacturing Method | Best For Materials | Primary Application | Lifespan/Durability |

|---|---|---|---|---|

| Electroplated | Single layer of diamonds bonded with nickel coating. | Glass, ceramic, soft porcelain, fibreglass. | Delicate jobs needing a very fine finish. | Short |

| Vacuum Brazed | Diamonds bonded to the exterior in a vacuum furnace. | Hard porcelain, marble, granite, cast iron. | All-purpose drilling, wet or dry cutting. | Medium to Long |

| Sintered | Diamond particles mixed with metal powder and fused under heat/pressure. | Reinforced concrete, hard stone, asphalt. | Heavy-duty, high-volume professional work. | Very Long |

Choosing between these comes down to balancing the demands of your material with your budget and how often you'll be using the bit. Each one has its place in a well-stocked toolkit.

The real magic of a diamond drill bit isn't just in its construction; it’s seeing it at work across the UK’s toughest industries. From London’s sprawling construction sites to the specialised offshore platforms in the North Sea, these aren't just handy tools—they're fundamental to how modern Britain builds, engineers, and explores.

Their ability to cut cleanly and precisely through almost anything makes them indispensable for jobs that would bring conventional equipment to a grinding halt. They let professionals tackle the hardest materials with a level of confidence and accuracy that was once unthinkable.

In the UK’s ever-busy construction sector, a diamond drill bit is an everyday essential. On any big project, you’ll find contractors needing to create perfect, clean openings through heavily reinforced concrete. These holes are vital for running plumbing, electrical conduits, and HVAC systems. A standard bit would either shatter or cause dangerous structural damage through vibration.

Diamond core bits, on the other hand, simply grind their way through concrete and rebar, leaving a smooth, structurally sound hole behind. This isn't just neat; it’s critical for maintaining the integrity of everything from city high-rises to new motorway bridges. When you need to drill into hard materials like concrete, using the right tool is non-negotiable for both safety and quality. We dive deeper into this in our guide on choosing the right drill bit for concrete.

The ability to cut clean holes without causing micro-fractures in surrounding concrete is a key reason why diamond drilling is specified in major UK infrastructure projects. It’s a matter of long-term structural safety, not just convenience.

Away from the building site, the unique strengths of the diamond drill bit are crucial for finding what lies beneath our feet. Geologists depend on diamond core bits to pull up cylindrical samples from deep within the earth. These core samples are like a library of the earth's history, giving them invaluable clues about rock formations, mineral deposits, or ground stability for future developments.

This same technology is a cornerstone of the UK's energy sector. In the harsh environment of the North Sea, diamond-impregnated bits are the only things that can reliably chew through hard rock and complex geological layers to reach oil and gas reserves. The UK oil field drill bits market is actually set to grow, driven by new exploration and the need to get more out of existing fields. Polycrystalline diamond compact (PDC) bits are becoming the go-to choice here, loved for their incredible durability and efficiency in such demanding conditions.

The versatility of diamond bits even extends to high-end finishing work, like intricate custom tile trends where absolute precision is everything. From the foundations of a skyscraper to the finest details in a designer bathroom, the impact of these incredible tools is felt across countless professional trades.

Picking the right diamond drill bit isn't just a matter of finding one that fits your drill. It’s a calculated decision that makes all the difference to the quality of your work, how fast you get the job done, and how long your tools last. Get it right, and you'll be rewarded with clean, efficient cuts every single time.

The whole process really comes down to a few critical factors you need to weigh up before you even think about starting. From the material you’re tackling to the specs of your drill, each piece of the puzzle plays a vital role. If you ignore even one, you could end up with a burnt-out bit, a damaged workpiece, or just painfully slow progress.

First things first: what are you drilling into? Materials aren't just ‘hard’ or ‘soft’—their specific characteristics determine exactly which type of diamond bit you need. The two key properties to get your head around are hardness and abrasiveness.

A good rule of thumb is to match the bond of the bit to the material you’re cutting:

Your equipment is the next piece of the puzzle. There’s a world of difference between a powerful, professional-grade core drill and a standard handheld one, especially when it comes to torque and speed (RPM). Every diamond drill bit is engineered to work best within a specific RPM range.

Using a bit at a speed that's too high will generate a massive amount of heat, quickly 'glazing' the diamonds and making the bit pretty much useless. But run it too slowly, and the diamonds won’t be able to cut effectively, which will kill your efficiency. Always check the manufacturer's recommended RPM and make sure your drill can sit comfortably within that range.

Finally, think about the size of the hole you need and the environment you’re working in. The diameter and depth will dictate how much power you need and whether you can get a continuous supply of water to the bit.

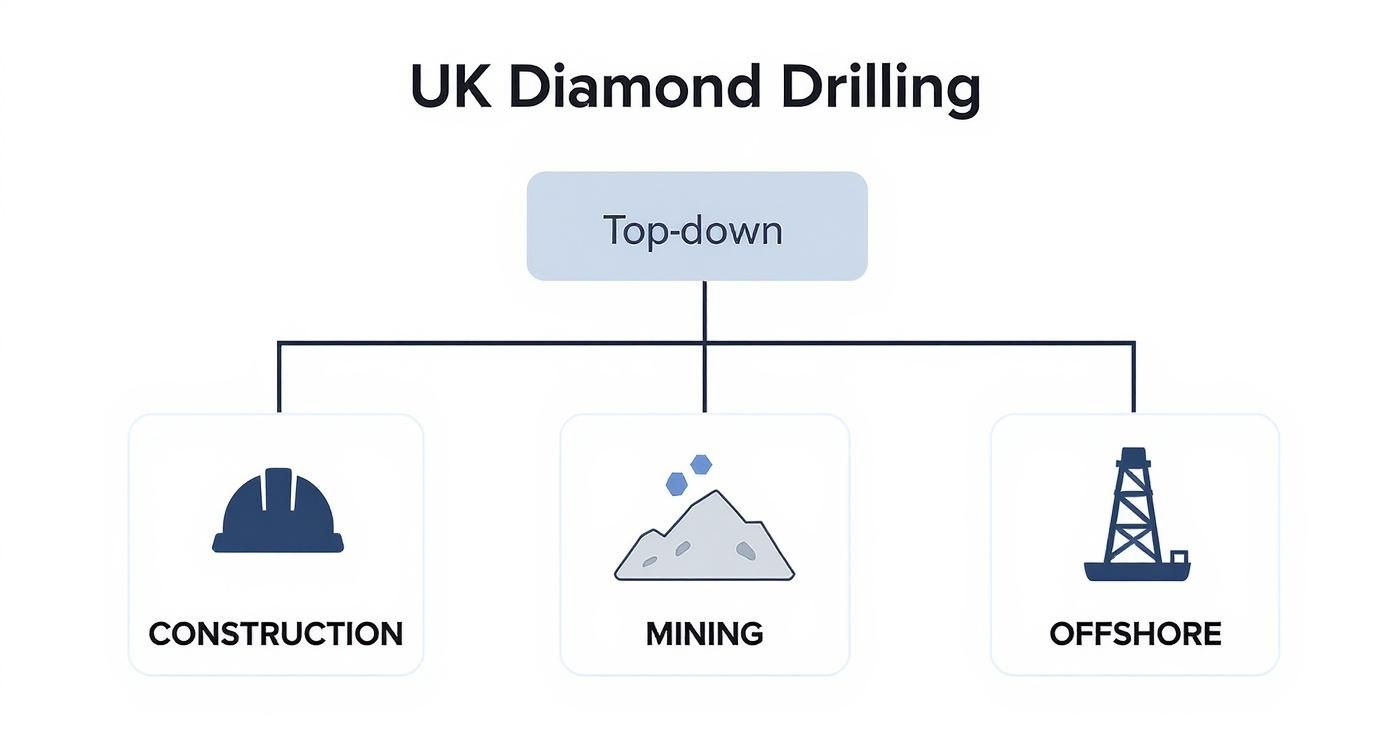

This decision tree gives you a good idea of how these factors come together across major UK industries like construction and mining.

As the infographic shows, specialised jobs—from offshore exploration to heavy construction—all call for their own unique drilling strategies and tools. This brings us neatly to the final big decision: are you drilling wet or dry?

Honestly, wet drilling is almost always the better way to go. Water is the perfect coolant, stopping the bit from overheating while also flushing away all the dust and debris. This doesn't just make the bit last longer; it also gives you a faster, cleaner cut.

Of course, dry diamond bits exist for those times when using water just isn’t practical. But they’re really designed for short, intermittent bursts of work and are generally less efficient for more demanding jobs. By carefully thinking through these four factors—material, drill, dimensions, and method—you can confidently pick a diamond drill bit that will give you the best possible performance and value for money.

Having the best diamond drill bit on the market is only half the story. The real secret to a perfect hole and a long-lasting tool lies in your technique. It’s easy to think that pushing harder will speed things up, but with diamond drilling, the opposite is true.

You have to let the diamonds do the work. All that’s needed is steady, moderate pressure to let the bit grind away at the material. Pushing too hard creates a huge amount of heat, which can quickly dull the diamond particles in a process called 'glazing'. It also massively increases the risk of cracking brittle materials like porcelain or glass.

For almost any project you tackle with a diamond bit, water is your best friend. A constant flow of water over the drilling area gives you two massive benefits: it’s a powerful coolant and an effective lubricant. This stops the bit from overheating and helps flush away the abrasive slurry of dust and debris.

This one simple step will dramatically extend the life of your bit and give you a faster, cleaner cut. While some bits are designed for dry use, they’re really only for quick, one-off jobs. For any serious or prolonged drilling, wet is always the way to go.

One of the trickiest parts of the job is starting a hole on a slick surface like a glazed tile without the bit wandering all over the place. There’s a simple but brilliant technique for this: start drilling at a 45-degree angle.

This method gives the bit an anchor point, stopping it from skating across the surface and ensuring you get a perfectly placed hole every single time.

Crucial Tip: Never, ever use the hammer function on your drill with a diamond bit. The percussive action is designed to chip material away, which will shatter the delicate diamond bond and destroy your bit almost instantly. Always stick to the rotary-only setting.

Running the drill too fast is another recipe for disaster. Excessive speed creates friction and heat—the number one enemy of any diamond tool. As a general rule, the larger the diameter of the bit, the slower your RPM should be. Always check the manufacturer's speed recommendations to protect your investment.

Whether you're using standard bits or specialised diamond tile drill bits for angle grinders, getting the technique right is what separates an amateur job from a professional result.

You don't have to look far to see that the demand for high-performance diamond drilling is on the rise across the United Kingdom. This isn't just a small shift; it's a direct response to the massive scale of UK infrastructure programmes, ambitious urban renewal projects, and ongoing resource exploration.

As construction standards get tougher and more precise, the need for tools that deliver on both accuracy and efficiency has never been more critical. Your average drill bit just can't handle the challenge of cutting through modern composite materials or heavily reinforced concrete without risking the structure's integrity. This is exactly where the unique grinding action of a diamond drill bit becomes indispensable.

The economic ripple effect of this demand is huge. Focusing just on core bits, the UK's diamond drill bit market was valued at roughly £70 million in 2024. That number is set to climb, pushed forward by the relentless pace of the construction and mining sectors. These industries have become completely reliant on advanced tools that can chew through hard rock and dense concrete without slowing down. For a deeper dive into these numbers, you can check out the Europe Diamond Core Bit Market Report.

This steady growth really highlights a fundamental change in the industry. The diamond drill bit is no longer a niche, specialist tool. It's now seen as a cornerstone for achieving the speed, accuracy, and safety essential for today's most demanding projects.

From drilling clean conduits in new skyscrapers to carrying out geological surveys for future resources, diamond drilling is central to the UK's industrial and economic muscle. This market trend isn't just a statistic; it proves how vital these tools have become. With continued investment in national infrastructure, the need for these powerful, precise tools will only grow, cementing their place in every serious professional's toolkit.

Even with the best guides, real-world questions always pop up once you get started. Let's tackle some of the most common queries to help you troubleshoot on the job and use your diamond drill bits like a pro.

For smaller jobs, like drilling into ceramic tiles or glass, your standard rotary drill will probably do the trick. The key is to disable the hammer function, keep the speed low, and make sure you have a constant trickle of water to keep things cool.

But if you're facing down tougher materials like reinforced concrete or need to drill larger holes, it’s time to call in the big guns. A dedicated core drill rig with a built-in water feed isn't just a suggestion—it's essential for getting the job done safely and effectively.

More often than not, this happens when the diamonds on your bit have "glazed over." Think of it like the surface becoming polished and smooth, losing its bite. This is usually a sign of overheating or using the wrong bond for the material—for instance, a hard-bond bit on soft, abrasive material can cause the metal matrix to smear over the diamonds.

Luckily, there's a simple fix: you need to "dress" the bit. Just drill into something highly abrasive, like a cinder block or a proper dressing stone, for a few seconds. This scrapes away the smeared metal and exposes a fresh, sharp layer of diamond particles, bringing your bit right back to life.

Let's be clear: wet drilling is always the better method for any diamond drill bit. Using a continuous flow of water is non-negotiable for top performance, and here’s why it’s so important:

Sure, dry drilling bits exist. They're built to handle higher temperatures, but they should only be a last resort for quick, shallow holes where using water is absolutely impossible. For any serious work on hard materials, wet drilling is the only way to go for the best performance, a clean finish, and your own safety.

Ready to tackle your next tough drilling project with confidence? Explore the full range of high-performance diamond drill bits and accessories at Neasden Hardware. Find the perfect tool for any material by visiting our online store today.